Noise Vibration and Harshness Automotive (NVH)

NVH stands for Noise Vibration and Harshness. It refers to the analysis & study of reducing unwanted sounds and vibrations that drivers and passengers experience inside a vehicle. NVH meaning in the automotive industry relates to the overall refinement of the driving experience by minimising noise vibration and harshness inside the cabin.

NVH Testing in the Automotive Industry

Automotive NVH Solutions plays an important role in vehicle design, helping to improve comfort & make the driving experience more enjoyable. Most automobile manufacturers place significant emphasis on NVH testing in vehicle design to deliver smoother, quieter, and more comfortable driving experiences for their customers.

In simple terms:

- Noise is what you can hear.

- Vibration is what you can feel.

- Harshness is how much the noise, bumps, and vibrations affect the vehicle cabin and its passengers.

These terms describe the sounds and movements you experience in a vehicle. Harshness is felt as sudden jolts or tremors, usually in the speed range of 20 to 100 Hertz. Reducing these vibrations so that passengers do not find them disturbing is a key goal when designing the drivetrain.

Importance of NVH in Automotive

Why is NVH in vehicles so important? The answer is comfort, safety, & brand value. Here's why NVH automotive is given serious attention:

- Passenger Comfort: Less noise & vibration mean a more peaceful ride.

- Driver Focus: Reduced noise vibration and harshness automotive prevents driver fatigue.

- Safety: Excessive vibrations can damage parts over time. Proper NVH solutions help avoid such issues.

- Brand Image: Premium brands focus on Noise Vibration and Harshness automotive performance to enhance customer satisfaction.

- Customer Expectations: Buyers now expect smooth & quiet rides, making NVH solutions essential. A low NVH car isn't just quieter, it offers a better overall experience.

How is NVH Analysis Conducted?

Car noises come from many sources: humming tires, whistling wind, squeaky wipers, & more. These noises can be heard. Noise vibration and harshness analysis helps engineers identify and reduce the undesirable ones, ensuring a better NVH automotive experience. To optimise Noise Vibration and Harshness automotive performance, engineers use acoustic simulation tools to study noise behaviour at different design stages.

Acoustics Simulation Levels

- Full-Vehicle Level: Noise produced by the entire car when in motion.

- System Level: Noise from systems working together (engine + gearbox).

- Sub-System Level: Noise from a particular machine, like an e-motor.

- Component Level: Noise from a specific part, like a seatbelt click.

For accurate NVH automotive results, engineers create detailed simulation models that mimic real-world behaviour. Tools like Ansys Mechanical, Ansys LS-DYNA, Ansys Fluent, Ansys Motor-CAD, & Ansys Maxwell are commonly used. Ansys Sound helps post-process these models to fine-tune the NVH car performance.

These tools are key for noise vibration harshness testing in modern vehicle design.

NVH Analysis and Solutions

An NVH engineer specialises in identifying, analysing, & solving NVH automotive issues. NVH engineers run tests both in labs and on the road to find solutions.

How NVH Engineers Work?

- Acoustic Tests: Measure sounds from the engine, exhaust, & wind.

- Vibration Tests: Check shaking or movement in seats, pedals, or steering.

- Harshness Tests: Evaluate comfort over rough roads or bumps.

Once the tests are complete, NVH solutions are developed to reduce unwanted noise & vibrations.

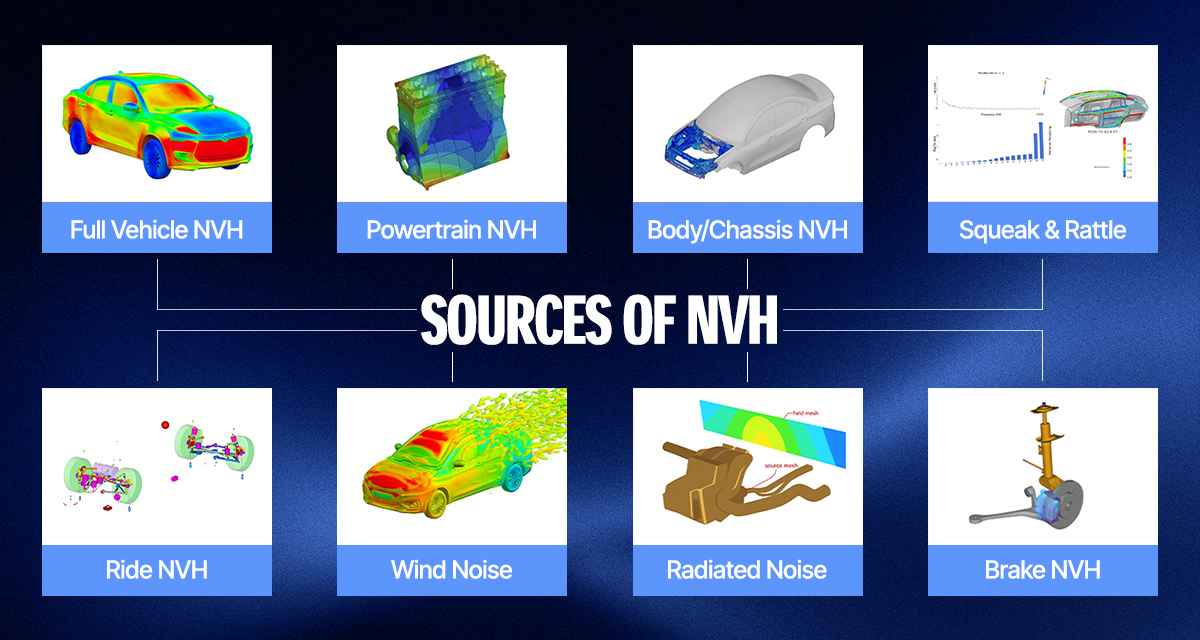

Sources of NVH in Cars

Understanding the cause of noise vibration and harshness automotive is the first step to fixing it. To understand NVH better, it’s important to know what each part stands for:

- Noise: Sounds that come from the engine, tires, wind, or brakes.

- Vibration: Shaking or movement felt through the steering wheel, seats, or pedals.

- Harshness: The unpleasant feeling caused by a mix of noise & vibration, making the ride uncomfortable.

Common NVH automotive sources include:

Engine and Powertrain

Engines, transmissions, & gearboxes generate noises and vibrations, especially during acceleration.

Suspension System

A poor suspension setup passes road bumps into the cabin, creating harshness.

Tires and Road Contact

Tires produce noise and vibration depending on road quality.

Aerodynamics and Wind

Wind noise increases at higher speeds without proper car design.

Brakes and Steering

Even braking and steering can cause vibrations and sound if not designed well.

Recognising these sources helps NVH engineers provide better NVH automotive solutions.

Challenges in NVH Simulation

A common mistake in NVH automotive simulations is jumping straight to complex models. Complex simulations require time & heavy computing power, especially when planning for complex mobility solutions like autonomous vehicles, but if the base model isn’t accurate, the results will fail to match real-world behaviour. This wastes both time and money.

Before moving to detailed simulations, engineers should ensure basic model accuracy in terms of mass, stiffness, & damping. These should match real tests through methods like:

- Modal Assurance Criteria (MAC)

- Coordinate Modal Assurance Criteria (CoMAC)

- Frequency Response Assurance Criteria (FRAC)

This step ensures that the final noise vibration harshness testing results are reliable and match actual vehicle performance.

How NVH Solutions Reduce Vehicle Noise & Improve Driving Comfort?

Good NVH automotive practices lead to better car designs. Here’s how noise vibration harshness testing helps:

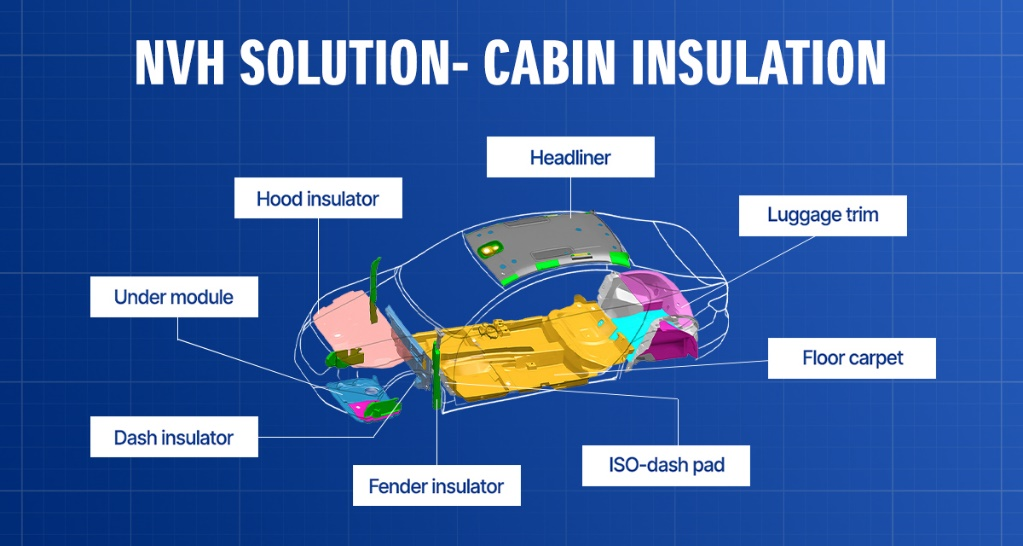

Cabin Insulation

Materials like sound-deadening foams reduce road and traffic noises.

Engine Isolation

Special engine mounts absorb engine vibrations, making the ride smoother.

Improved Suspension

Modern suspension designs reduce the impact of potholes & rough roads. NVH engineers conduct detailed noise vibration and harshness analysis for the overall vehicle refinement.

Technology Integration

- Active Noise Cancellation (ANC) cancels out noise through speakers.

- Vibration dampers lower shaking across the vehicle body.

Design from the Ground Up

In the Noise Vibration and Harshness automotive industry, engineers focus on reducing NVH to enhance overall performance. Advanced materials like acoustic glass are tested and implemented.

What Are the Latest Innovations in NVH Control Technologies?

The world of NVH automotive is evolving fast. Here’s what’s new in automotive NVH solutions:

Electric Vehicles (EVs)

EVs are quieter but still have NVH standards challenges. Innovations focus on eliminating motor vibrations and road noise.

Lightweight Materials

Materials like aluminium reduce weight while controlling noise vibration harshness automotive effectively.

Digital Simulations

Before building the vehicle, simulations predict noise vibration harshness automotive behaviour, saving time.

AI and Machine Learning

AI helps predict how changes impact NVH standard car performance, speeding up the solution process.

Smart Materials

Materials that change shape or stiffness based on conditions help reduce vibrations actively noise vibration and harshness automotive testing.

3D-Printed Components

Custom shapes help control vibration and noise better.

These innovations show that NVH automotive solutions are smarter and more advanced than ever.

Conclusion: Why NVH in Vehicles Matters More Than Ever?

In today’s world, NVH automotive isn’t just a feature; it’s an expectation. The future will bring even better automotive NVH solutions with smart technology. It gives drivers the quiet, smooth, & refined rides they deserve.

The importance of NVH in vehicles cannot be ignored. Whether it’s reducing unwanted noises or improving ride quality, NVH automotive plays a vital role in making your drive comfortable. From daily commutes to long drives, a low NVH car enhances your experience.

NVH engineers at Suzuki R&D India (SRDI) use the latest tools for noise vibration and harshness analysis. They help the brand deliver smoother, quieter rides. Proper NVH testing ensures safety, durability, and customer satisfaction in every vehicle.